INNOVATION THROUGH CONSILIENCE

根据镀膜工艺、晶体管元件性能和应用,选择各种有机半导体材料

| Formulation | Coating Method | Mobility | |||

|---|---|---|---|---|---|

| Spin | Slot-die | Inkjet | Gravure | ||

| CP3100 | ● | ● | ● | ● | 0.5 ~ 1.0 |

| CP4100 | ● | ● | ● | ● | 0.3 ~ 0.6 |

| CP5100 | ● | ~ 4.0 | |||

| CN5100 | ● | ● | ● | ● | ~ 0.5 |

Planarization Layer A5XXX

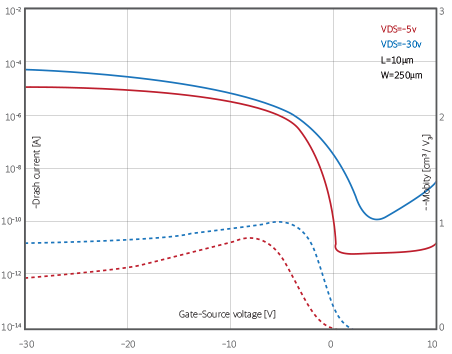

CP3100 Series

ㆍEnable aSi replacement

ㆍMobility up to 1㎠/Vs

CP4100 Series

ㆍMobility up to 1㎠/Vs

ㆍCross-linkable semiconductor

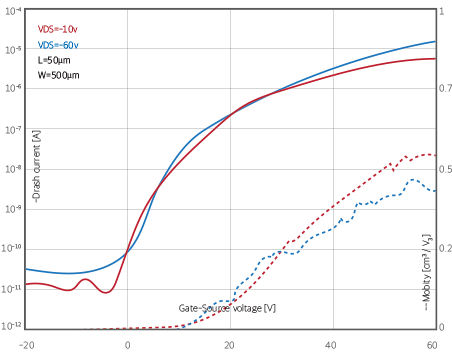

CP5100 Series

ㆍMobility up to 4㎠/Vs

CN5000 Series

ㆍMobility up to 1.5㎠/Vs

CD2200 Series

ㆍThermally cross linking dielectric

CD7100 Series

ㆍUV photopatternable dielectric

Inkset C1000SP

ㆍBased on CP3100

ㆍOptimized for spin coating

Inkset C2000SL

ㆍBased on CP5100

ㆍOptimized for slot die or blade coating of OSC

Inkset C3000S

ㆍInkset for Metal Layer

X-Ray Detector Fingerprint Sensor

X-Ray Detector

Display Backplanes OLED, Micro-LED

ㆍ适用于各种镀膜方法的有机p-type半导体材料

·具有均匀的元件特性与优秀的大气稳定性

·使用Non-halogenated溶剂配制墨

·可适用于Bottom-gate和Top-gate晶体管结构

·流动性 0.5~1 cm2/Vs

·On/Off ratio > 106

·a-Si元件性能可在低价材料中体现

| Method | Viscosity(mPas) | Availability | Applications |

|---|---|---|---|

| Spin-coating | 1.0 – 2.0 | ● |

EPD, LCD (display backplane) Logic Circuits, Sensors (in logistics, packaging, …) |

| Slot-die coating | 1.0 – 8.0 | ● | |

| Inkjet printing | ● | ||

| Gravure printing | ● | ||

| Stripe coating | 0.5 – 3.0 | ● | |

| Flexographic printing | ● |

ㆍ具有优秀的有机半导体液体和元件的空气稳定性

·使用Non-halogenated溶剂配制墨

·可适用于Bottom-gate和Top-gate晶体管结构

ㆍ流动性 ~0.5 cm2/Vs

ㆍ所有工序都可以在PET基材上进行

| Method | Viscosity(mPas) | Availability | Applications |

|---|---|---|---|

| Spin-coating | 0.5 – 1.5 | ● |

EPD, LCD (display backplane) Logic Circuits, Sensors (in logistics, packaging, …) |

| Slot-die coating | 1.0 – 8.0 | ● | |

| Inkjet printing | ● | ||

| Stripe coating | 0.5 – 3.0 | ● |