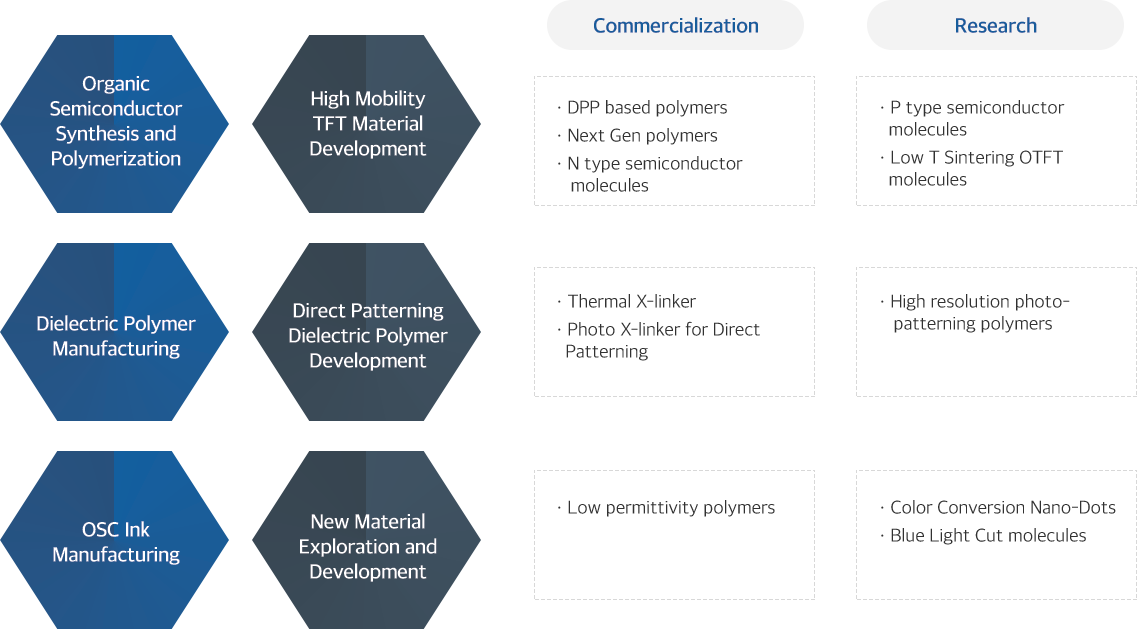

INNOVATION THROUGH CONSILIENCE

코팅공정, 트랜지스터 소자 성능 및 응용에 따라 다양한 유기 반도체 재료 선정

| Formulation | Coating Method | Mobility | |||

|---|---|---|---|---|---|

| Spin | Slot-die | Inkjet | Gravure | ||

| CP3100 | ● | ● | ● | ● | 0.5 ~ 1.0 |

| CP4100 | ● | ● | ● | ● | 0.3 ~ 0.6 |

| CP5100 | ● | ~ 4.0 | |||

| CN5100 | ● | ● | ● | ● | ~ 0.5 |

Planarization Layer A5XXX

CP3100 Series

ㆍEnable aSi replacement

ㆍMobility up to 1㎠/Vs

CP4100 Series

ㆍMobility up to 1㎠/Vs

ㆍCross-linkable semiconductor

CP5100 Series

ㆍMobility up to 4㎠/Vs

CN5000 Series

ㆍMobility up to 1.5㎠/Vs

CD2200 Series

ㆍThermally cross linking dielectric

CD7100 Series

ㆍUV photopatternable dielectric

Inkset C1000SP

ㆍBased on CP3100

ㆍOptimized for spin coating

Inkset C2000SL

ㆍBased on CP5100

ㆍOptimized for slot die or blade coating of OSC

Inkset C3000S

ㆍInkset for Metal Layer

X-Ray Detector Fingerprint Sensor

X-Ray Detector

Display Backplanes OLED, Micro-LED

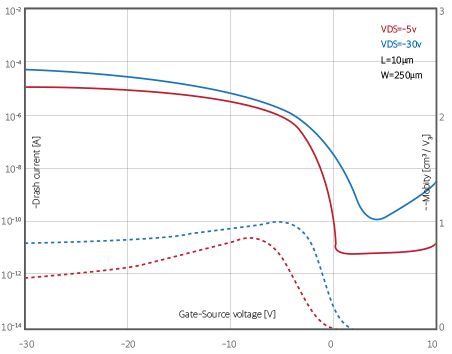

ㆍ다양한 코팅방식에 적합한 유기 p-type 반도체 재료

ㆍ균일한 소자 특성과 우수한 대기 안정성 보유

ㆍNon-halogenated 용매를 이용한 잉크 조액

ㆍBottom-gate와 Top-gate 트랜지스터 구조에 적합하게 적용 가능

ㆍ이동도 0.5~1 cm2/Vs

ㆍOn/Off ratio > 106

ㆍa-Si 소자 성능을 저가 기재에서 구현 가능

| Method | Viscosity(mPas) | Availability | Applications |

|---|---|---|---|

| Spin-coating | 1.0 – 2.0 | ● |

EPD, LCD (display backplane) Logic Circuits, Sensors (in logistics, packaging, …) |

| Slot-die coating | 1.0 – 8.0 | ● | |

| Inkjet printing | ● | ||

| Gravure printing | ● | ||

| Stripe coating | 0.5 – 3.0 | ● | |

| Flexographic printing | ● |

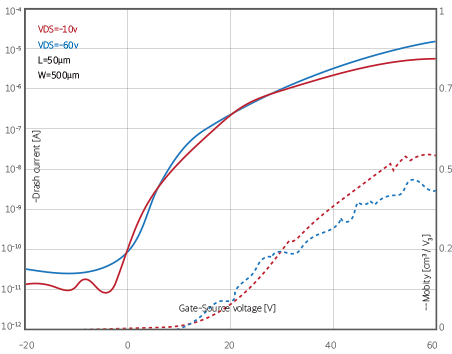

ㆍ유기 반도체 조액과 소자의 우수한 공기 안정성 보유

ㆍNon-halogenated 용매를 이용한 잉크 조액

ㆍBottom-gate와 Top-gate 트랜지스터 구조에 적합하게 적용 가능

ㆍ이동도 ~0.5 cm2/Vs

ㆍPET 기재에 모든 공정이 가능

| Method | Viscosity(mPas) | Availability | Applications |

|---|---|---|---|

| Spin-coating | 0.5 – 1.5 | ● |

EPD, LCD (display backplane) Logic Circuits, Sensors (in logistics, packaging, …) |

| Slot-die coating | 1.0 – 8.0 | ● | |

| Inkjet printing | ● | ||

| Stripe coating | 0.5 – 3.0 | ● |