INNOVATION THROUGH CONSILIENCE

Selection of various organic semiconductor materials according to coating process, transistor device performance and application

| Formulation | Coating Method | Mobility | |||

|---|---|---|---|---|---|

| Spin | Slot-die | Inkjet | Gravure | ||

| CP3100 | ● | ● | ● | ● | 0.5 ~ 1.0 |

| CP4100 | ● | ● | ● | ● | 0.3 ~ 0.6 |

| CP5100 | ● | ~ 4.0 | |||

| CN5100 | ● | ● | ● | ● | ~ 0.5 |

Planarization Layer A5XXX

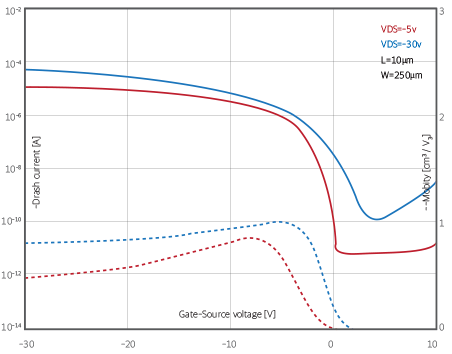

CP3100 Series

ㆍEnable aSi replacement

ㆍMobility up to 1㎠/Vs

CP4100 Series

ㆍMobility up to 1㎠/Vs

ㆍCross-linkable semiconductor

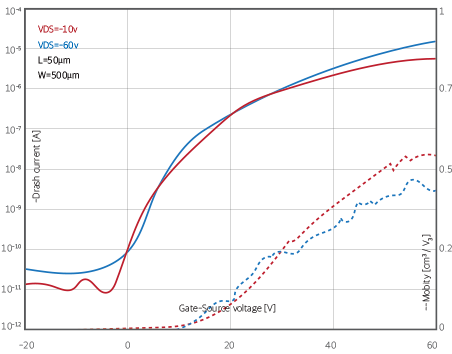

CP5100 Series

ㆍMobility up to 4㎠/Vs

CN5000 Series

ㆍMobility up to 1.5㎠/Vs

CD2200 Series

ㆍThermally cross linking dielectric

CD7100 Series

ㆍUV photopatternable dielectric

Inkset C1000SP

ㆍBased on CP3100

ㆍOptimized for spin coating

Inkset C2000SL

ㆍBased on CP5100

ㆍOptimized for slot die or blade coating of OSC

Inkset C3000S

ㆍInkset for Metal Layer

X-Ray Detector Fingerprint Sensor

X-Ray Detector

Display Backplanes OLED, Micro-LED

ㆍp-type Organic semiconductor material suitable for various coating methods

ㆍPossessing uniform device characteristics and excellent atmospheric stability

ㆍManufacturing ink by using non-halogenated solvent

ㆍApplicable to bottom-gate and top-gate transistor structures

ㆍMobility 0.5~1 cm2/Vs

ㆍOn/Off ratio > 106

ㆍa-Si device performance can be realized at low cost

| Method | Viscosity(mPas) | Availability | Applications |

|---|---|---|---|

| Spin-coating | 1.0 – 2.0 | ● |

EPD, LCD (display backplane) Logic Circuits, Sensors (in logistics, packaging, …) |

| Slot-die coating | 1.0 – 8.0 | ● | |

| Inkjet printing | ● | ||

| Gravure printing | ● | ||

| Stripe coating | 0.5 – 3.0 | ● | |

| Flexographic printing | ● |

ㆍManufacturing liquid of organic semiconductors and having excellent air stability

ㆍManufacturing ink by using non-halogenated solvent

ㆍApplicable to bottom-gate and top-gate transistor structures

ㆍMobility ~0.5 cm2/Vs

ㆍAll processes are available on PET materials

| Method | Viscosity(mPas) | Availability | Applications |

|---|---|---|---|

| Spin-coating | 0.5 – 1.5 | ● |

EPD, LCD (display backplane) Logic Circuits, Sensors (in logistics, packaging, …) |

| Slot-die coating | 1.0 – 8.0 | ● | |

| Inkjet printing | ● | ||

| Stripe coating | 0.5 – 3.0 | ● |