INNOVATION THROUGH CONSILIENCE

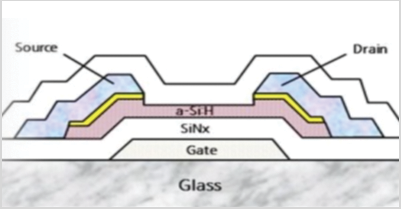

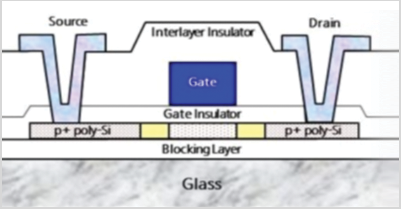

| Category | a-Si on Glass | LTPS on Plastic | OTFT on Film |

|---|---|---|---|

| Process Temp. | 300 °C | 250 °C | 100 °C |

| Process | CVD, Dry Etcher, PVD Sheet by Sheet process |

CVD, Dry Etcher, PVD Sheet by Sheet process |

Wet(Liquid) coating and development Roll to Roll process |

| No. of Mask | 4~5 | 7~11 | 4~5 |

| Mobility | 0.1 ~ 1.0 cm2/Vsec | 20 ~ 100 cm2/Vsec | 0.5 ~ 4 cm2/Vsec |

| Off Current(A) | >10-12 | 10-14~10-12 | >10-14 |

| Substrate | Glass | Soluble PI | PET, PEN, PI, Poly-ketone, PC etc |

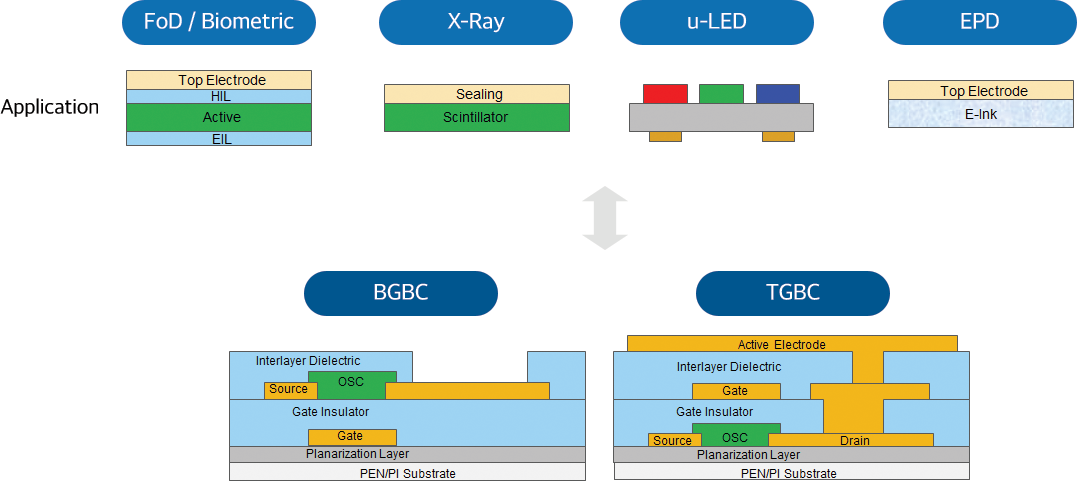

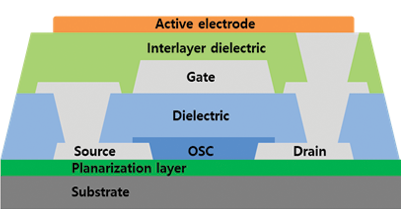

| OTFT Stacking Structure |  |

|

|

|

|

|

|

|

|---|---|---|---|---|---|---|---|---|

| Detail Process | Surface Treatment | S/D Electrode | OSC | Gate Insulator | Gate Electrode | Inter layer Dielectric | Cathode Electrode | |

| Organic material Coating | Spin | ○ | ○ | ○ | ○ | |||

| Slot Die / Inkjet | ○ | ○ | ○ | ○ | ||||

| PR Coating | Spin | ○ | ○ | ○ | ○ | ○ | ○ | |

| Slot Die | ○ | ○ | ○ | ○ | ○ | ○ | ||

| DFR | ○ | ○ | ○ | ○ | ○ | ○ | ||

| Electrode | Vacuum Deposition | ○ | ○ | ○ | ||||

| Electroless Plating | ○ | ○ | ○ | |||||

Specialties/Strengths

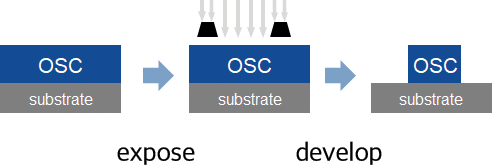

ㆍEliminate 3 Step (PR Coating, Etching, Strip)

ㆍNo need to use photoresist

ㆍCrosslinked material is not affected by subsequent processing